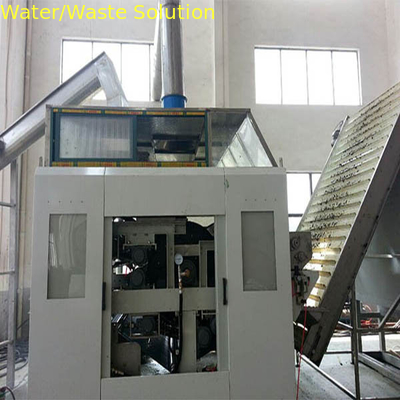

Electro-osmotic sludge dewatering machine

Running Principle:

Electro osmotic dewatering and drying technology is a newly developed sludge dewatering technology, it combines solid-liquid separation technology and Physical electrochemical processing technology together to carry out dewatering by electricity with multi unique feature such as making active sludge moisture content drops below 60% which the other mechanical dehydration is difficult to achieve , compared to other dewatering technology, and it is specially applied in outstanding biological sludge dewatering efficiency.

To make the sludge particles and water molecules separates and moves by imputing enough DC voltage toward the sludge, Which can realize dewatering without providing High voltage

Craft Flow Diagram;

Technical Characteristics :

1. High dewatering efficiency, system operating flexibility: realize large sludge area by adjusting the current strength and can separate bonder water easily and the sludge dryness can increased 30%-50%(Biochemical or high organic matter sludge )

2. Characteristics of dewatered cake – multi methods of the subsequent resource disposal: with little water content cake , it is beneficial for later incineration, composting and fill , if it is active sludge , it have high temp bacterial killing effect

3. Lower running cost: During operating process , Each 1 ton sludge dewatering (from 80% reduced to 55%)will only consumes 70-8 0KW/H , No heat generated by the electrolysis of electricity consumption is less than 1%, rinse water is less than 1t / h, compressed gas 0.2m3 / h, significantly saving energy

4. Independent Modular:can run with site existing dehydrating machine to further reduce cake water rate without bearing limit from heat media and other auxiliary material. it can directly

5. Safety and environmental Protection:

There is several insulated layers and deodorant protection around electricity parts,the total sludge dewatering process can realize within 5-8 minutes with small odor and little water in filter slag, after dewatering , the filtrate can directly return to sewage treatment system without secondary pollution.

6.Simple Craft

Easy operation and maintenance, high level auto control system, no need rebuild factory, and chemical or auto dosing system

7.Little Investment

Due to its simple craft with little auxiliary facility, only one main engine collecting into electricity can finish total dewatering process , total investment will be USDS 15000-25000/ metric ton

Electro-osmosis sludge drying system constitutes

1. Electrode: Electrode and shape

2.Cloth:Cloth should choose cake stripping, insulation, heat resistance of the filter cloth

3. Electric charge generating device penetration

4.Mechanical pressure and residue thickness

The idea residue thickness is between 5mm and 15mm, and the matching pressure is(0.1—0.3kg/cm2)as best economical solution .

Applicant field and dewatering efficiency table

|

Sewage and municipal sludge

|

Dewatering efficiency 80% __ 55%

|

|

Electroplating sludge

|

Dewatering efficiency 80% __ 60%

|

|

Algae, cyanobacteria sludge

|

Dewatering efficiency 80% __ 58%

|

|

Pharmaceutical sludge

|

Dewatering efficiency 80% __ 55%

|

|

Chemical sludge

|

Dewatering efficiency 80% __ 50%

|

|

Petrochemical oily sludge

|

Dewatering efficiency 80% __ 55%

|

|

Leather sludge

|

Dewatering efficiency 80% __ 50%

|

|

Sewer and river sludge

|

Dewatering efficiency 70% __ 40%

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!