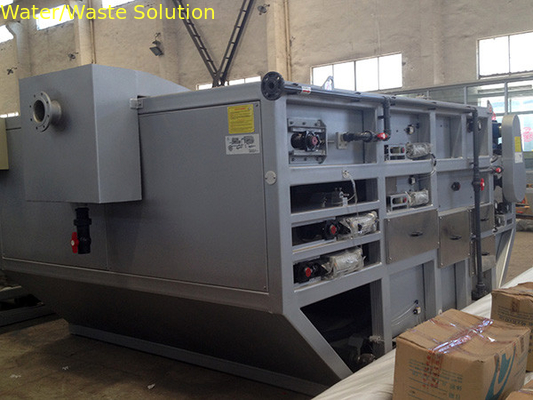

Belt concentrated pressure filter

Description:

Belt concentrated filter press is a kind of efficient continuous running solid-liquid separation equipment by integrating sludge thickening and de-watering together.

1. Applicant

It is widely applied in such fields as chemical industry, metallurgy, mining, food, paper, urban water supply and drainage industry with simple and applicable craft, investment-saving , short sludge retaining time , high efficiency of dephosphorization and dehydration

2. Model Instruction

BTF

BTF

Effective filter cloth width(mm)

Effective filter cloth width(mm)

Belt concentrated pressure filter

3. Feature

1. Elongated gravitational zone

2. Effective belt width increases by 150 mm

3. More press rolls consist of a reasonable roll system

4. Strengthen initial pressure roller press force distribution design

4. Structure and Working Process

It is mainly composed of both belt-type concentrated and filter dehydration sections . Each section consists of drive mechanism, sludge distribution mechanism, filter belt correction mechanism, tension, guide and discharge mechanism as well as frame likewise. Besides,the filter section includes various press rolls.

The fully mixed and flocculated sludge will be evenly distributed over the inclined section after flowing into the feed distribution box of the concentrated section,this section mainly purpose is to remove the free water from the material and reduce the material flow for the next step preparation. The sludge will quickly wipe out large free water as the movement of the filter cloth under the multiple mud rake guidance of and gravity. The concentrated sludge after gravity dehydration is further dewatered by the reversing mechanism, which is conveyed to the gravity dewatering zone of the pressure filter section. And then into the S-squeeze section, in which the sludge was sandwiched between the upper and lower filter belts to carry on further dehydration after several s-shaped arrangement of the press roll on the filter cake.

When the belt passes through the discharge mechanism, the cake is scraped from the filter belt by the scraper. Throughout the concentrated press filter stage, the filter belt is constantly being automatically cleaned.

Equipment outline drawing, technical parameters and civil conditions see below charts

Equipment outline drawing

| Item /Model |

BTF1000 |

BTF1500 |

BTF2000 |

BTF2500 |

| Inlet Height H1(mm) |

2166 |

2218 |

| Outlet Height H2(mm) |

1250 |

| Long L(mm) |

6655 |

6870 |

| Width B(mm) |

1950 |

2450 |

2950 |

3450 |

| Height H(mm) |

2400 |

2480 |

| Sludge inlet(DN) |

125 |

125 |

200 |

200 |

Technical parameters Table

| Item /Model |

BTF1000 |

BTF1500 |

BTF2000 |

BTF2500 |

| Belt Width (mm) |

1150 |

1650 |

2150 |

2650 |

| Belt Speed (m/min) |

Concentrated Section:3.5~17.5m/min, Press Section:1~5m/min |

| Main Motor Power(kw) |

1.1+0.55 |

1.5+0.75 |

2.2+0.75 |

3+1.1 |

| Clean water pressure(Mpa) |

<0.5 |

| Clean water Volume(m /h3) |

10~ 12 |

18~ 20 |

22~ 25 |

35~ 40 |

| Run Weight (kg) |

5100 |

6600 |

8540 |

10000 |

| Water inlet moisture(%) |

98~99.5 |

| Sludge outlet water moisture (%) |

75~85 |

| Capacity (m /h3) |

15~40 |

20~60 |

25~80 |

40~100 |

5. Craft Flow Diagram

Civil Condition Table

| Item /Model |

BTF1000 |

BTF1500 |

BTF2000 |

BTF2500 |

| L1(mm) |

630 |

730 |

| L2(mm) |

1390 |

1400 |

| Concentrated base width B1(mm) |

1450 |

1950 |

2450 |

2950 |

| Pressed base width B2(mm) |

1650 |

2150 |

2650 |

3150 |

| Total Width B(mm) |

2650 |

3150 |

3650 |

4150 |

Sample parameters and pictures are for reference only, we will change it continuously to subject to both final confirmation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!