LSS Type Static Sieve

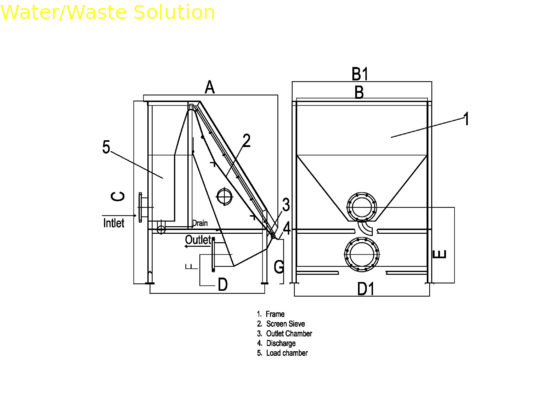

The working principle and structure

The main part of the Static Sieve is a S.S. curved or flat screen area made of wedge steel bar. The waste water to be treated is evenly distributed to the inclined screen surface through the overflow weir. Due to the small gap between the screen surface and the back gap, The water is smooth, not easy to block; solid material is retained, filtered water from the sieve gap in the outflow, while under the action of water, the solid material is pushed to the bottom of the sieve discharge, so as to achieve solid-liquid separation purposes.

Static sieve can effectively reduce the concentration of suspended solids in water and the running load on the subsequent process. It can be also used in solid-liquid separation and recovery of useful substances, of the industrial production. It is an excellent free powered filtration or recovery device of suspended solids, floating debris, sediment and other solid or colloidal substances.

Also called curve screen,inclined screen,hydraulic screen etc;

Scope of application:

Suitable for a variety of different types, different sizes of wastewater treatment project. Remove floating, suspended solids, center of gravity, etc., as a primary treatment, the alternative to the pond, reduce post-processing work, strengthen the unblocked biological treatment process, save operating cost. Also used in a variety of solid-liquid mixture concentration;

Typical applicable industry:

1. Paper making waste water ----- recycle fiber,remove solids;

2.Tannery waste water------- remove fur and feather,oil grease etc solids ;

3.Slaughtering waste water------remove fur,oil grease,feces etc solids;

4.Municipal domestic sewage-----remove fur,sundries etc solids;

5. Alcohol, starch factory wastewater, removal plant fiber shell's, groceries and other solid objects etc;

6. Pharmaceutical factory, sugar refinery wastewater, remove all kinds of waste residue, such as plant shell's etc solids;

7. malt beer factory wastewater, removal of malt, bean curd and other solids;

8. Livestock fish farms - removing clutter of livestock MAO, excrement and solid content etc solids;

9. Fish and meat processing plant - gut, scales, ground meat, fat and other solid. Other such as the characteristic, textile, chemical, plastic processing plants, large factory, hotel, residential sewage etc pretreatment;

Main technical data

| Model |

Nominal flow rate ( m3/h) |

| Filtering gap (mm) |

| 0.25 |

0.5 |

1.0 |

1.5 |

| LSS60 |

9 |

22 |

40 |

60 |

| LSS90 |

12 |

35 |

60 |

80 |

| LSS120 |

18 |

45 |

80 |

100 |

| LSS150 |

22 |

55 |

95 |

130 |

| LSS200 |

28 |

72 |

125 |

160 |

| Model |

A |

B |

B1 |

C |

D |

D1 |

E |

F |

G |

Inlet |

Outlet |

Drain |

| LSS60 |

1350 |

600 |

700 |

1800 |

1100 |

670 |

900 |

300 |

550 |

DN100 |

DN150 |

DN65 |

| LSS90 |

1350 |

900 |

1000 |

1800 |

1100 |

970 |

900 |

300 |

550 |

DN150 |

DN200 |

DN65 |

| LSS120 |

1550 |

1200 |

1300 |

2100 |

1300 |

1270 |

900 |

350 |

550 |

DN200 |

DN250 |

DN65 |

| LSS150 |

1550 |

1500 |

1600 |

2100 |

1300 |

1570 |

900 |

350 |

550 |

DN250 |

DN300 |

DN65 |

| LSS200 |

1550 |

2000 |

2100 |

2100 |

1300 |

2070 |

900 |

350 |

550 |

DN250 |

DN350 |

DN65 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!