Fiber Turntable Cloth Filter

https://www.facebook.com/bruce.xiong.758/videos/1364257643760463

Standard Specification

| Model |

Disc DN (mm) |

Gross Filter Area(m2) |

Max Capacity (m3/D) |

Total Power (KW) |

Remark |

| LFCF-2.0-2 |

2000 |

11.6 |

2000 |

2.25 |

Non-standard equipment, configuration and size will be adjusted according to actual requirements |

| LFCF-2.0-4 |

2000 |

23.2 |

4000 |

2.25 |

| LFCF-2.0-6 |

2000 |

34.8 |

6000 |

3.00 |

| LFCF-2.0-8 |

2000 |

46.4 |

8000 |

4.50 |

| LFCF-2.0-10 |

2000 |

58.0 |

10000 |

5.20 |

| LFCF-2.0-12 |

2000 |

69.6 |

12000 |

5.20 |

| LFCF-2.5-2 |

2500 |

17.8 |

3400 |

2.95 |

| LFCF-2.5-4 |

2500 |

35.6 |

6800 |

2.95 |

| LFCF-2.5-6 |

2500 |

53.4 |

10200 |

3.70 |

| LFCF-2.5-8 |

2500 |

71.2 |

13600 |

6.60 |

| LFCF-2.5-10 |

2500 |

89.0 |

17000 |

6.60 |

| LFCF-3.0-4 |

3000 |

51.4 |

9800 |

3.70 |

| LFCF-3.0-6 |

3000 |

77.0 |

14700 |

3.70 |

| LFCF-3.0-8 |

3000 |

103.0 |

19600 |

6.60 |

| LFCF-3.0-10 |

3000 |

128.6 |

24500 |

6.60 |

| LFCF-3.0-12 |

3000 |

154 |

29400 |

6.60 |

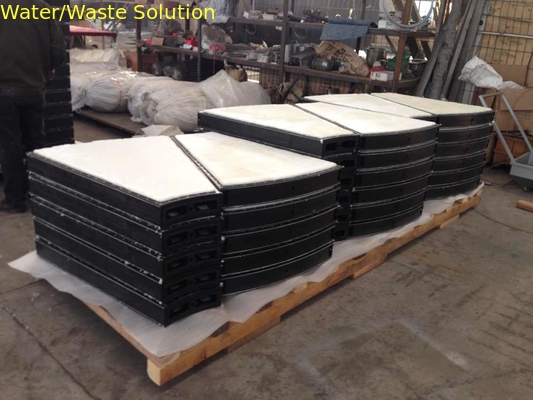

Tank Structure Design

1. Product Overview

This Cloth Filter adopted by 700 wastewater treatment plants around the world is one of the most advanced filters in the world with good treatment effect, high effluent quality and stable operating function .

2. Product use:

Mainly applied for both cooling circulating water treatment and recycling use after deep treatment of wastewater

As cooling or recycled waste water applicant:

the influent water quality SS<=80 mg/l, and

the effluent water quality SS<=20 mg/l,

For advanced deep treatment of sewage by following fields after conventional activated sludge method, delayed aeration method, SBR system, oxidation ditch system, drip filter system and oxidation pond system:

1. Removal of the total suspended state

2. Combined with dosing agent to remove phosphorus;

3. Can remove heavy metals

The Cloth turntable filter is used to filter the effluent from the activated sludge final settling tank.

Influent water quality: SS: 30 mg/l (maximum 80-100 mg/L,

Effluent water quality: SS: <5 mg / l turbidity <= 2NTU.

The actual running water is better,

the general effluent turbidity is around 1

3. Working Principle

Its operating state is divided into two relatively independent and simultaneous processes of raw water filtration and backwashing. Both are done in different locations on the same filter.

A Raw Water Filtration:

Filtration: externally enters and exits, the gravity flow of sewage enters the filter tank, so that the filter disc is completely immersed in the sewage. A water raft is provided in the filter tank to make the water in the filter tank uniform and the water inlet to generate low disturbance. The sewage is filtered through a filter cloth, and the filtrate is collected through a hollow tube and discharged through a water effluent. Filtration is still in progress during the cleaning process. Therefore, the filtration is continuous throughout the operation.

The sewage to be filtered enters the inner side of the filter transmission center cylinder by gravity drop, and the rotating center cylinder is provided with a square water distribution hole. The sewage flows into the drum through the water distribution port and enters the filter tray inner liner, and then passes through the filter cloth, so that the suspended matter in the sewage is intercepted on the inner side of the filter disk, and the filtered water is discharged through the overflow collecting water. The equipment is in a static state during filtration, which is beneficial to the sedimentation of the bottom of the sludge.

B. Backwashing:

Part of the sludge in the filtration is adsorbed in the fiber wool filter cloth, and the sludge layer is gradually formed. As the sludge accumulates on the filter cloth, the filter resistance of the filter cloth increases and the water level of the filter rises gradually. The pressure sensor in the filter monitors the liquid level change in the tank. When the liquid level in the tank reaches the cleaning set value (high water level), the PLC can start the backwash pump and start the cleaning process. The backwash time and period can be adjusted. The sludge on the filter cloth passes through the back suction device and exits the drainage system of the plant through the backwash water pump. The filter can be continuously filtered during cleaning.

During the cleaning, the filter carousel rotates at a speed of 0.5 to 1 rpm. The backwashing pump negative pressure suctions the surface of the filter cloth, sucks up the sludge particles accumulated on the filter cloth, and the water in the filter turntable is simultaneously sucked from the inside to the outside, and the filter cloth is cleaned. The instantaneous flushing area only accounts for about 1% of the area of the full filter turntable, and the backwashing process is intermittent.

During normal cleaning, two filter turntables are grouped, each time cleaning a set of filter discs, and by automatically switching the electric valve control on the suction pump pipe, the cleaning of each group in the complete cleaning process of the fiber turntable filter is alternately performed. The operation of the suction pump is continuous during this time. When the influent water quality suddenly deteriorates and the backwash cycle is ≤15 minutes, the system will start emergency measures, and start 2~4 backwashing pumps at the same time, and backwash the 2~4 sets of filter turntables (4~8 turntables) until The backwash cycle returned to normal.

C. The sludge discharge:

in the sludge is collected inside the filter cloth and gradually forms a sludge layer. As the sludge accumulates on the filter cloth, the filter resistance of the filter cloth increases and the water level of the filter pool gradually increases. A bucket-shaped bottom is arranged under the filter turntable of the fiber turntable filter, which is beneficial to the collection of sludge at the bottom of the pool. The sedimentation at the bottom of the sludge tank reduces the amount of sludge on the filter cloth, which can extend the filtration time and reduce the amount of backwash water. After a set period of time, the PLC starts the mud pump and returns the sludge to the drainage system of the plant through the perforated pipe at the bottom of the tank. Among them, the interval between mud discharge and the duration of mud discharge can be adjusted. In addition, when the treatment system in front of the filter fails, the mud discharge system can be activated to play the role of emptying the filter.

4. Main features

A. 24 hours Continuous operation with no stop backflushing

B. The treatment effect is good by filtering less than 10 um particle size C. 1% ~ 2% of total intake backwashing water consumption

D. 0.05 - 0.25 m Small head loss

E. Low operating costs (regardless of phosphorus removal and dosing) operating costs are less than 0.01 Yuan / ton of water.

F installed power is low.

G. Fully automatic control with no operator management

H. Small footprint lead to large filter area by upright disc design.

I Short design and construction Period, fit for reconstruction in future

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!