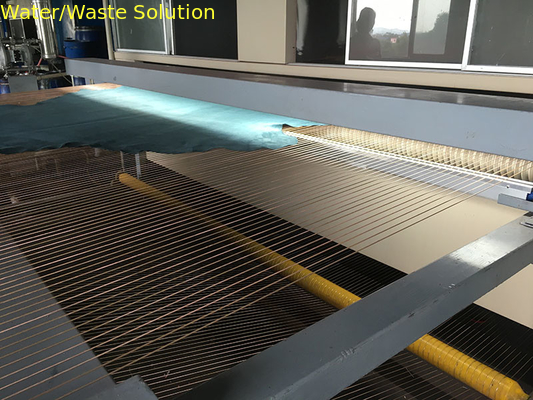

low temperature Continous heat pump sludge drying machine

| Specification /Model |

LDC-1500 |

LDC-2000 |

LDC-3000 |

LDC-4000 |

LDC-5000 |

LDC-6000 |

LDC-8000 |

LDC-10000 |

LDC-12000 |

LDC-16000 |

LDC-20000 |

| Daily Sludge Disposal (kg) |

1500 |

2000 |

3000 |

4000 |

5000 |

6000 |

8000 |

10000 |

12000 |

16000 |

20000 |

| Daily Water disposal ( L) |

1,000 |

1,333 |

2,000 |

2,667 |

3,333 |

4,000 |

5,333 |

6,667 |

8,000 |

10,667 |

13,333 |

| Water disposal per hour ( L) |

42 |

56 |

83 |

111 |

139 |

167 |

222 |

278 |

333 |

444 |

556 |

| Dryer Dimension: L*W*H (m) |

5.0*3.6*3.4 |

5.5*3.8*3.4 |

6.5*3.8*3.4 |

7.0*4.0*3.4 |

8.5*4.0*3.4 |

8.5*4.2*3.4 |

10.5*4.2*3.4 |

13.0*4.2*3.4 |

15.0*4.2*3.4 |

20.0*4.2*3.4 |

20.0*4.5*3.4 |

| Total Power ( kw ) |

17 |

23 |

34 |

45 |

56 |

67 |

89 |

112 |

134 |

178 |

223 |

| Power Consumption (KW) |

220/380/440/460 3ph , 50/60hz |

| Control System |

Man-machine interface + PLC |

| Inlet Material Moisture |

70%-85% |

| Outlet Material Moisture |

10%-50% |

| Wet Sludge Shaping Condition |

Extruced to be strip shape |

| Cooling Way |

By air |

It can dry those sludge with 80% moisture through Plate frame press filter , Belt press filter and centrifugal decanter

into sludge with moisture 10% , it can thickened the sludge volume into 3/4 of the original one without needing extra

auxilary energy by only consuming the heat source under the total closed drying condition and its full auto control system

we are the first global auto design , research and make this kind of batch sludge dyrer manufacturer and leader due to our decade effort and concern on it .

♦ Sludge Process ♦

70~85% water content sludge is fed from the top of the indirect heating dryer.There are several layers of dryer.The function of scraping arms of each layer is moving sludge to next layer until dryer discharge port at lowest layer.There could ba a storage bag for temporary storage at discharge port or it is delivered to treated sludge storage tank.During sludge moving procedure,sludge is stirring by scraping arms.It is dramatically increased slidge drying efficiency by combined heat,mass transfer and stirring physical reactions.

♦ Air Circulation Process ♦

Dry air is fed into the bottom of the dryer.It goes from the bottom layer to the discharge vent of upper layer of the dryer.When dry air passes through the sludge surface of each layer,the moisture inside sludge is quickly vaporized into air as humidity of air increased.The near saturated air from the discharge vent of dryer is boosted pressure by fan.The dehumidification function is occurred in condenser.The air will be dried again after leaving condenser.Due to reduce the dew point temperature,vapor molecules move together to form condensation droplets collected in condensate tank.Dry air could directly go to dryer or pass air heater before go to dryer due to different sludge characteristics.The air has been continuous circulating in the system.Since there is no exhaust released to environment during process.It is not necessary to do oder or exhuast treatment.

♦ Water Circulation Process ♦

lced water is pumped into condenser and taken out the heat of the air.It becomes the cold water after leaving condenser.The cold water is pumped through heat pump which adsorbed heat and make cold water to be iced water again.The iced water is circulating back to condenser.Hot water is pumped into the air heater and release heat to air before it is fed into dryer.After leaving air heater,hot water becomes warm water.The warm water is pumped through heat pump which release heat and make warm water to be hot water again.The hot water is circulating back to air heater.

Characteristic of our Low Temperature Batch Dryer

1. improve its dry sludge into 90% to withdraw the growth of the micro creature ( sludge heat value equal 3000Kcal /kg under 10% moisture )

2. The Water Steam will be consendated at 5 degree cecus .

3. Strenghten the drying system safety :

Dust concentration <60 g/m3; Grain Temp.<110 degree cecus; oxegen Content <12%; total drying system with no dust under air speed <2

m/s; the drying temp. control between 55 and 95 degree cecus;

4. With odorless smelling

5. small footprint

6. very easy and convenience on its operation and maintenance

7.Lower investment and Lower Maintenence charge

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!