RDS Series Micro Drum Screen Filter

1.Applicant

In Pretreatment of STP, ETP, WWTP to filter 30%-60% organic suspend solid in influent by continuous working thus to reduce the disposal load of next process.it is different from traditional screen esp. fit for MBR Process to effectively improve the processing efficiency

2. Drum Filter Feature

A. SS304/SS316L Integrated Structure

B. External Spray System

C.Sealing cover plate;

D.4-20 rpm Speed Regulation Range

E.Automatic slag blow

F. Time back flush

G. Optiaonal Choose

A.SS316L Integrated Structure

B.Liquid level switch;

C.Backwash solenoid valve;

D.Backwash pump;

E.Electric control cabinet.

3.Charateristic

1.High Interception Rate (Almost all Grid Slag with High Efficiency)

2. No Block Happen by Adapting Wedge grid or punching screen elements

3. Large Flow Rate and reduces head loss.

4. Corrosion-Resistance SS Material fit for high temp. and high concentration liquid filtration.

5.Drum Type Design with large filtering area and compact room and energy consumption

6. Auto or hand control backflushing Nozzle to clean onside impurities freely

7. Fully Automatic Work without operator supervision

8. Fully Closed Design to get rid of secondary pollution

9. Easy to maintain and Replace

4. Construction and Working Process

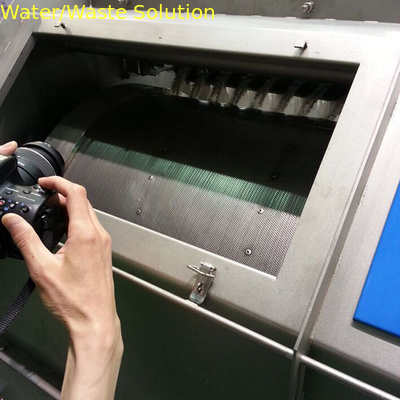

Construction

It consists of drum screen, support roller unit, drive mechanism unit, backwash cleaning system, unloading mechanism, cover plate assembly, access door, frame and filtrate collection bucket.

Working Process:

The drum is horizontally supported by four wheels, and is driven by TEFC reducer, anti-corrosion roller chain and stainless-steel sprocket. The spray system automatically sprays clean water. Its integrated design, sturdy construction, and high-quality stainless-steel materials ensure that the equipment can run for long periods of time with low energy consumption without trouble, and is easy to maintain. The overflow trough extends to the inside of the drum, and raw water flows in from the overflow trough, and is evenly injected into the inner wall of the drum through the distribution of the weir. The filtered raw water is guided to the central drainage area through the floor deflector and flows into the next sewage treatment unit; the slag in the raw water is blocked on the inner surface of the drum filter, and is discharged through the inner wall as the drum rotates The slag is conveyed spirally to the tail slag hopper. As the drum head rotates, the entire screen surface can be continuously or intermittently sprayed by an external spray system.

5. Model Selection and Parameter

6. Why Us?

A. Exported to Israel and USA for large quantiies with Excellent Performance and Competitive Price

B. Little maintenance and fast response on servive in one hour

C. Smooth Running for at Least 10 years

7. Touch US Freely

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!